| Building & Construction Materials |

- PVC Foam Boards

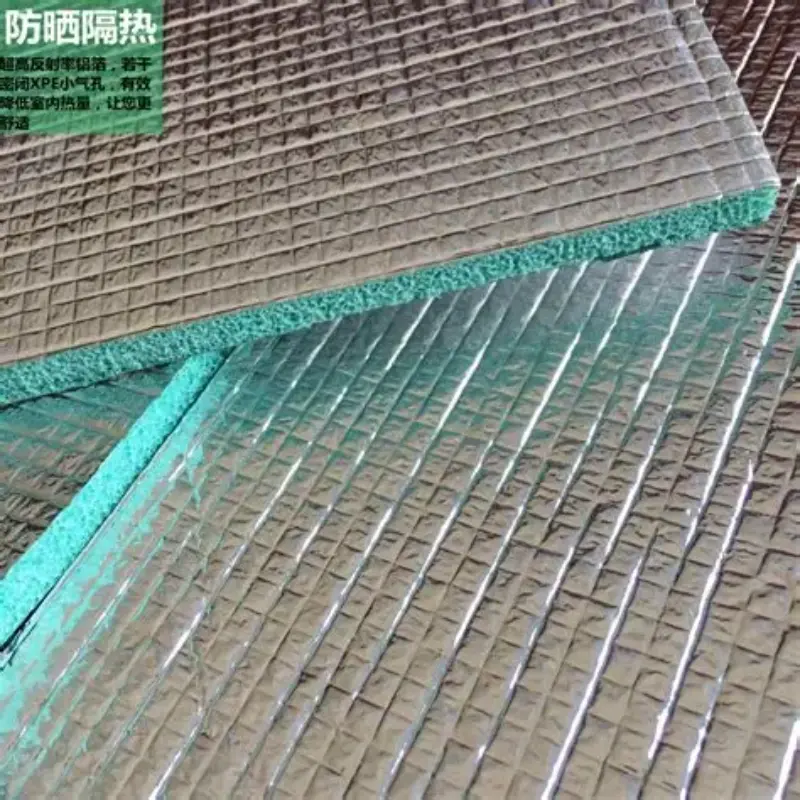

- XPE Foam Insulation Panels

- EVA Foam Sealing Strips |

- Lightweight

- Thermal Insulation

- Structural Integrity |

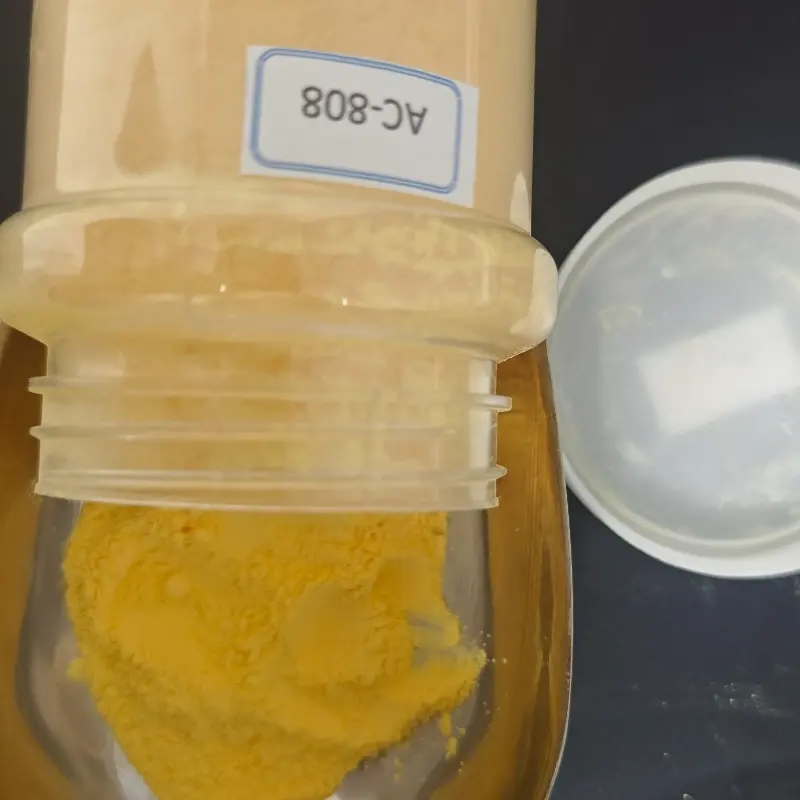

- High gas generation for efficient foaming and weight reduction.

- Wide process compatibility suitable for board and profile extrusion.

- Good material compatibility with PVC, XPE, and EVA. |

| Packaging Industry |

- PS Foam Containers

- Foam Packaging Inserts

- Protective Foam Cushions |

- Shock Absorption

- Lightweight

- Cost-Effectiveness |

- High gas generation capacity maximizes foam expansion, reducing material usage.

- Suitable for PS which is widely used in packaging.

- Customizable particle sizes can optimize processing for different packaging designs. |

| Footwear & Sports Goods |

- EVA Foam Shoe Soles

- Sports Mats

- Yoga Mats |

- Comfort & Cushioning

- Durability

- Elasticity |

- Excellent performance with EVA for soft, comfortable foam products.

- High gas generation creates a desirable cell structure for cushioning.

- Original powder form allows for easy compounding with colorants and additives. |

| General Industrial & Consumer Products |

- Injection Molded Foam Handles

- Foam Gaskets

- Decorative Foam Trims |

- Design Flexibility

- Processability

- Cost-Effectiveness |

- Suitable for injection molding enabling complex foam part production.

- Wide material compatibility (PVC, PS, EVA) for diverse product lines.

- Customizable particle sizes can improve flowability and mold filling in injection molding. |